Cone platinum is not a term that appears frequently in mainstream discussion, but in technical, manufacturing, and materials engineering circles, it is rapidly becoming a subject of interest. Unlike traditional uses of platinum in jewelry or catalytic converters, “cone platinum” represents a specialized form of the metal, engineered and shaped for extreme precision in high-temperature, high-pressure environments.

In this deep exploration, we uncover what cone platinum actually is, why it’s gaining importance, how it’s used in fields from ceramics to aerospace, and what the future holds for this highly niche but technologically significant material. If you’re looking to understand the full value chain—from elemental characteristics to industrial use cases—this is your definitive guide.

Understanding Cone Platinum: A Specialized Form

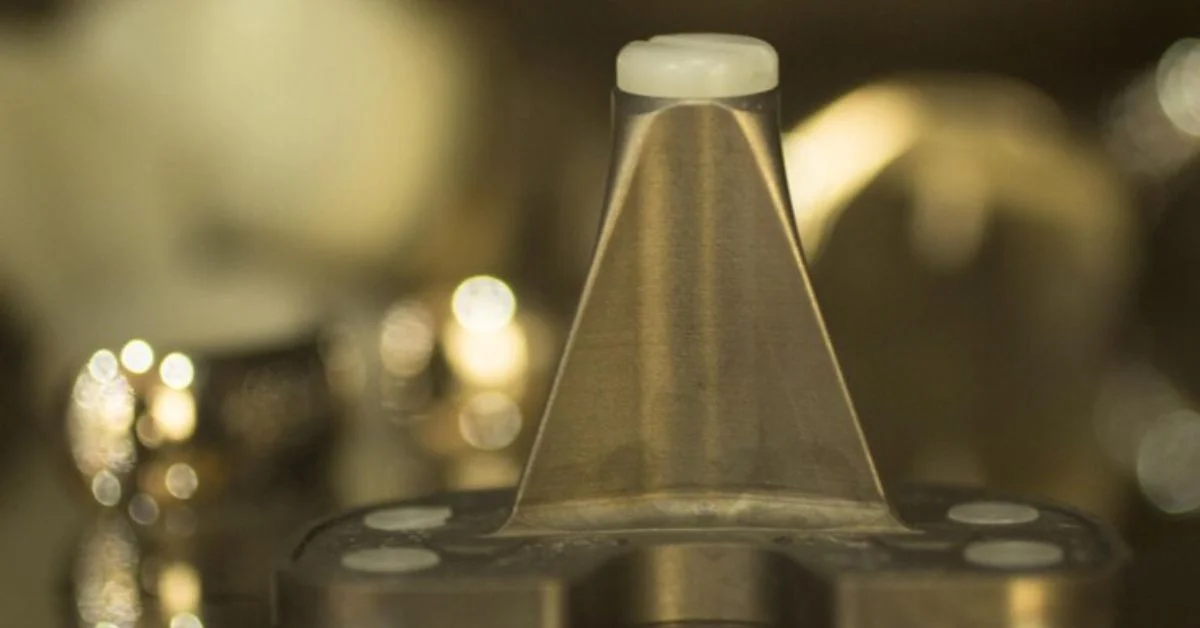

The term “cone platinum” refers to platinum components that are precision-shaped—most often into conical geometries—for use in specific high-stress environments. These cones are not merely aesthetic or convenient shapes; they are critical to the function of the systems they serve.

This form is most commonly found in:

- High-temperature furnaces

- Laboratory crucibles and thermocouples

- Ceramic sintering operations

- Glassblowing and advanced metallurgy

- Aerospace propulsion material testing

Shaped platinum, particularly in conical forms, is chosen for its exceptional thermal stability, resistance to chemical erosion, and mechanical integrity under repeated stress cycles. When engineered precisely, these cones enable operations that would otherwise be impossible using standard alloys or base metals.

The Metallurgical Properties That Make Cone Platinum Unique

Platinum is a noble metal with several properties that make it suitable for extreme applications. In its conical form—often cast, milled, or drawn under precise metallurgical controls—these properties are intensified through geometry and design.

Key Characteristics of Cone Platinum:

- Melting Point: 1,768 °C (3,214 °F), making it one of the most heat-tolerant naturally occurring metals.

- Oxidation Resistance: Platinum does not oxidize in air, even at high temperatures, preserving its surface and strength.

- Chemical Inertness: It resists most acids and corrosive environments, including those found in chemical and ceramic manufacturing.

- High Density: Offers superior durability and stability during dynamic processes.

- Thermal Conductivity: Excellent for distributing heat evenly—essential in thermal management systems.

- Malleability and Ductility: Allows it to be shaped into fine conical points or thick-walled crucibles depending on design needs.

When platinum is fashioned into cones, especially with precise tip angles and wall gradients, it becomes a vital tool or component in controlled environments where failure is not an option.

Key Industries That Depend on Cone Platinum

1. Advanced Ceramics and Kiln Technologies

In ceramics, particularly porcelain and industrial ceramic fabrication, platinum cones serve as thermometric guides. This application is deeply rooted in the cone firing system, where conical pyrometric indicators are placed in kilns to gauge temperature accuracy and heat-work (the combination of time and temperature).

Why Platinum?

- Refractory cones made with platinum components provide the most reliable temperature benchmarks.

- Unlike clay or glass-based cones, platinum variants resist distortion at extremely high temperatures (up to 1,800 °C).

- In applications where ceramic materials are sensitive to slight fluctuations, platinum cone tools provide unparalleled stability.

These are common in the production of:

- High-resistance ceramics

- Military-grade refractory coatings

- Dental ceramics and biomedical implants

2. Laboratory Thermocouples and Crucibles

In advanced material testing, cone platinum is used in thermocouples—the junctions of dissimilar metals that measure temperature based on voltage differentials. Type S thermocouples (Platinum-Rhodium) often use cone platinum terminals for accuracy and durability.

Use Cases:

- Melting point determination

- Chemical reaction monitoring

- Pharmaceutical compound development

- Semiconductor wafer fabrication

Cone platinum also forms the base of small crucibles used to melt or analyze precious materials. The conical shape is ideal for funneling, measuring, and minimizing spatter in thermal labs.

3. Aerospace and Jet Propulsion Systems

In jet engine research, missile testing, and high-altitude simulation chambers, materials are subjected to immense heat, friction, and pressure. Cone platinum parts—especially tip modules, seals, and exhaust nozzles—play a crucial role in:

- Thermal shielding

- Propellant combustion analysis

- Heat transfer management

The metal’s strength and shape retention make it ideal for reusable test systems that must remain stable across dozens of cycles.

4. Glass Manufacturing and Precision Casting

Cone platinum is also used in shaping and finishing molds for luxury and technical glass products. These might include fiber-optic draw towers, where molten glass is pulled through platinum bushings that often feature conical geometries for flow control.

In precision casting, platinum cones act as nozzles or gating tools to control metal flow during vacuum casting of turbine blades, surgical tools, or microcomponents.

5. Medical and Bioengineering Applications

In niche biomedical applications, cone platinum is utilized in:

- Electrode fabrication for neural and cardiac devices

- Microinjection tooling in stem cell research

- Implanted thermal sensors in prosthetics

Its shape allows targeted application, while its inert nature reduces biological reactivity, making it ideal for internal use in short-term or long-term studies.

The Manufacturing Process: From Raw Platinum to Precision Cone

Creating cone platinum products requires an interdisciplinary fusion of metallurgy, machining, and design. The process typically involves:

- Sourcing and Refinement: Platinum is extracted and purified—usually from South African or Russian mines.

- Forming Blanks: The metal is cast into ingots or rods.

- Shaping: High-precision CNC machining or hand-forging forms the conical geometry.

- Annealing: The cone is heat-treated to ensure molecular uniformity and reduce internal stress.

- Finishing: Surface polishing, tip sharpening, and alloy blending (often with rhodium) finalize the product.

Quality control is critical. Microfractures, surface inconsistencies, or minute measurement errors can result in failure during use. This is why cone platinum products are often batch-tested using X-ray diffraction and electron microscopy.

Environmental and Economic Considerations

Environmental Footprint

Mining platinum is resource-intensive and not without ecological consequences. However, platinum is highly recyclable. Cone platinum used in industrial contexts is almost always recovered and reprocessed.

Environmental mitigation efforts include:

- Closed-loop manufacturing systems

- Ethical sourcing policies

- Recycling partnerships between manufacturers and clients

Cost Dynamics

Platinum’s high price—typically several hundred to a few thousand dollars per ounce—means cone platinum components are premium-grade. The cost is justified only when performance demands it.

Economically, demand is growing in:

- India and China (for ceramics and electronics)

- Western aerospace sectors

- Renewable energy testing systems

As alternative alloys improve, cone platinum may become more specialized rather than ubiquitous.

Future Trends in Cone Platinum Usage

Cone platinum’s role is likely to expand, albeit selectively. Future-forward applications include:

- Nuclear fusion research: Cones used in plasma nozzles and radiation shielding.

- Quantum computing: Precision thermocouple integration within cryogenic testing chambers.

- Nano-manufacturing: Micro-cones used in thermal nano-probes and AI chip cooling systems.

- High-speed rail and electric vehicle batteries: Materials testing in gigafactories.

As manufacturing processes become smaller and hotter, platinum’s durability and thermal management capacity will remain in high demand. Conical forms will evolve in scale, perhaps shrinking from centimeters to nanometers.

Conclusion: A Metal of Precision, A Shape of Function

Cone platinum may sound like a niche topic, but it lies at the intersection of innovation, engineering, and endurance. Its properties are timeless—resistance, purity, reliability. Yet, it is the shape—the cone—that gives it precision in purpose.

From ceramics to spacecraft, cone platinum quietly ensures that our most critical systems run at full potential without faltering under pressure or heat. It is not a consumer product. It’s not decorative. But it is indispensable in systems where performance matters more than publicity.

In an era where technology races ahead, cone platinum is the anchor that ensures we do not lose stability along the way.

FAQs

1. What exactly is cone platinum?

Cone platinum refers to precision-engineered platinum components, usually conical in shape, used in high-temperature and high-pressure environments across industries like ceramics, aerospace, and laboratory science.

2. Why is platinum shaped into cones?

The conical shape optimizes heat distribution, flow control, and spatial efficiency in thermal and mechanical systems, enhancing the performance of the already robust metal.

3. What are the main applications of cone platinum?

Applications include thermocouples, kiln firing guides, jet engine testing modules, glass molding nozzles, and biomedical sensors.

4. Is cone platinum recyclable?

Yes. Most industrial cone platinum is recovered and recycled due to its high value and environmental considerations. Closed-loop systems are common in platinum manufacturing.

5. Will cone platinum become more common in the future?

It’s likely to become more specialized but not necessarily more widespread. As industrial technologies become more advanced, the need for precision, high-performance materials like cone platinum will continue to grow.

For more information, click here.